Sustainable Manufacturing Solutions and Consulting

Explore Energy Efficiency Solutions with Our Sustainability Consultants

Achieve your sustainability goals with our comprehensive approach. Utilize our wide-ranging solutions for maximum impact. Together, we can make a difference.

Ingenero’s Sustainability Solutions

Engineering expertise and digital transformation solutions for increased production, sustainability, efficiency and safety.

Energy

Renewables, Fuel, Electricity, Steam

Operational Reliability

Profitability, Safety

Emissions

GHG

Water

Usage, Pollutants

Safety

Process, People

Environmental Regulations

Air, Water, Waste, Material disposal & reuse

Yield

Resource use efficiency

Augmented Intelligence

A key part of Ingenero’s digital solutions, Augmented Intelligence is a hybrid approach utilizing cutting-edge technology together with human intelligence and domain expertise to create actionable insights.

The Ingenero Approach

Performance Tracking

- Smart Sustainability Dashboards provide efficient monitoring

- Plan vs Actual” tracking identifies gaps for improvement

- Real-time tracking of plant’s total emissions provides actionable insights for reduction

- Data analytics, soft sensors and predictive models provide timely insights

Decision Framework

- Equipment and systems with highest improvement opportunity are identified

- Solution is customized to identify and address underperformance and optimize energy consumption in critical systems

- Digital twins are utilized to provide accurate predictions of impact of change on entire process and quantify realistic reductions associated with each change

- Studies are done to optimize performance and further sustainability goals

Analyzing Results

- Sustainability gains are achieved while maximizing profitability and production.

- This Dashboard visualization illustrates opportunities for effective energy utilization and operating unit yields.

- Digital twins are utilized to provide accurate predictions of impact of change on entire process and quantify realistic reductions associated with each change

- Studies are done to optimize performance and further sustainability goals

Energy Efficiency Solutions: Audit and Optimize for Success

Net Zero

This change in direction reflects a broader commitment to environmental responsibility and aligns with global efforts to combat climate change. While challenges remain, the transition towards net-zero emissions represents a pivotal transformation in the energy sector, signaling a more sustainable future for the industry and the planet.

Energy Management System

Oil and gas companies are increasingly recognizing the urgency of addressing climate change and are making significant strides towards achieving net-zero emissions. Many industry leaders are investing in cleaner energy sources, carbon capture technologies, and sustainable practices to reduce their carbon footprint. Ingenero support this shift with our sustainability services

Root Cause Analysis (RCA)

At Ingenero, we excel at solving complex problems by using advanced tools like simulation models and techniques such as barrier, fault tree, and Kepner-Tregoe. Our systematic approach helps us dig deep into operational challenges and pinpoint their root causes with precision. This approach has allowed us to successfully tackle critical issues such as off-spec material production, inadequate output, equipment problems, high energy use, and frequent breakdowns.

Supply Chain Optimization

At Ingenero, we are experts in optimizing supply chains worldwide. With a strong record in various industries, we offer custom solutions that cut costs and boost operational capacity. Our tools help you analyze logistics and manufacturing, and our Decision Support Models aid in making smart decisions. We are known for solving profit-sharing complexities, consistently saving costs, and being your trusted global partner for supply chain optimization.

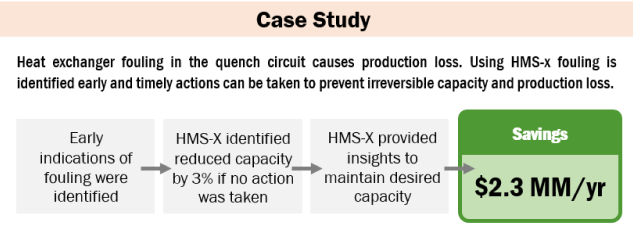

Case study

Frequently Asked Questions

Sustainable manufacturing involves creating products through economically sound processes that minimize environmental impacts, conserve energy and natural resources, and enhance employee, community, and product safety. This approach encompasses the entire product lifecycle, from design and production to disposal and reuse, aiming to reduce waste, optimize resource use, and lower emissions. By adopting sustainable practices, manufacturers can improve efficiency, reduce costs, and enhance their reputation, leading to long-term profitability.

Sustainable manufacturing companies reduce carbon footprints by using energy-efficient processes, recycling materials, and minimizing waste. They implement sustainable manufacturing technology to enhance efficiency while lowering emissions. Partnering with manufacturing process improvement consultants also helps optimize workflows, ensuring responsible resource usage and a commitment to environmental preservation.

Sustainable energy solutions lower operational costs, reduce emissions and improve efficiency. By integrating sustainable manufacturing engineering, companies can improve productivity while minimizing environmental impact. Partnering with manufacturing engineering consulting firms ensures proper implementation, leading to long-term savings, regulatory compliance, and improved brand reputation in an increasingly eco-conscious market.

Energy audits identify inefficiencies, reduce waste, and improve organizational performance. Manufacturing process improvement consultants assess consumption patterns, recommending sustainable manufacturing technology in order to lower costs and emissions. By optimizing systems, businesses improve resource utilization. This also ensures sustainability while boosting profitability and compliance with environmental regulations.

Digital tools optimize production, monitor energy use, and reduce waste. Sustainable manufacturing companies use automation, AI, and data analytics to achieve better efficiency. Manufacturing engineering consulting firms also implement smart solutions, ensuring continuous improvements in sustainable manufacturing engineering, reducing costs, and achieving eco-friendly goals.

Achieving net-zero emissions ensures long-term sustainability and regulatory compliance. Sustainable manufacturing companies adopt renewable energy, waste reduction strategies, and sustainable manufacturing technology to balance emissions. With support from manufacturing process improvement consultants, businesses achieve environmental responsibility while maintaining a competitive advantage.