Asset Performance and Reliability Solutions

Asset Performance Management with AI-Driven Solutions

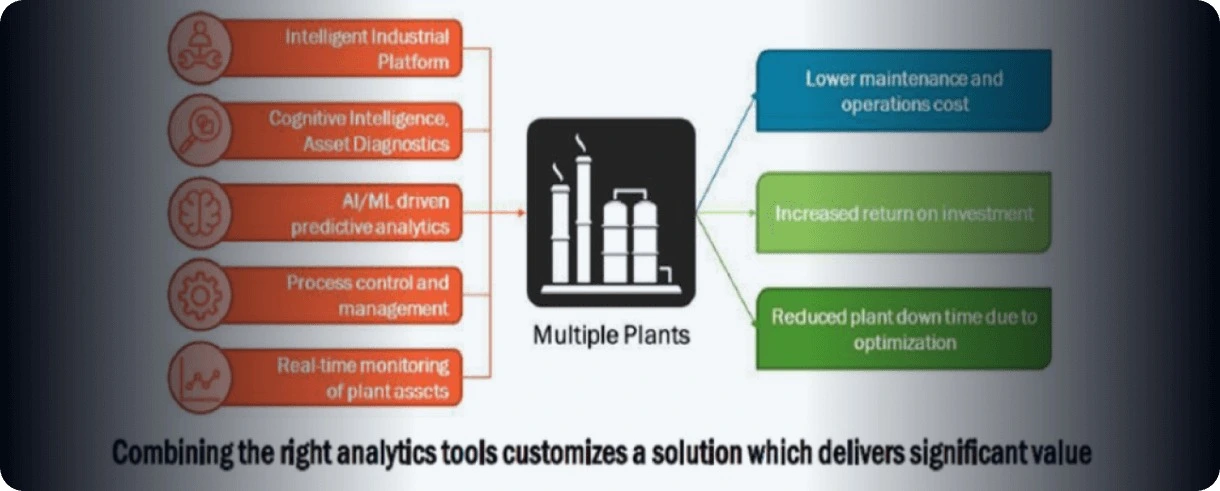

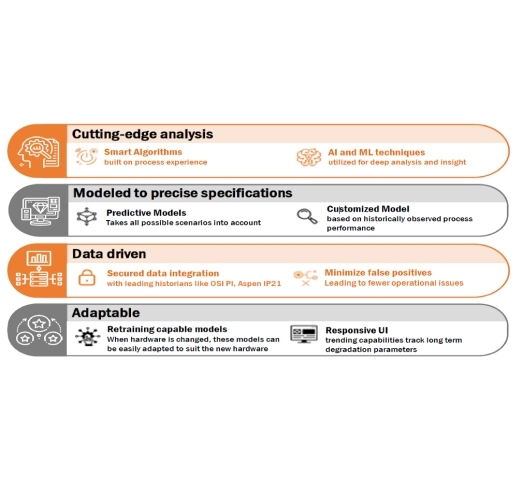

INGENERO’s Innovative Solutions for overall Asset Performance Management and Reliability using Applied AI

Features of INGENERO’s Asset Performance Management Solution:

Enhancing Exchanger Performance

Exchangers play a crucial role in various industrial processes, facilitating heat exchange between fluids. However, issues such as fouling, corrosion, and inefficiencies can significantly impact their performance. INGENERO with its HMS-X soluton for exchangers employs advanced AI algorithms to continuously monitor exchanger operations, detecting anomalies and predicting potential failures well in advance. By analyzing real-time data streams, including temperature, pressure, and flow rates, their AI-based solutions enable proactive maintenance interventions, optimizing performance and extending the lifespan of exchangers.

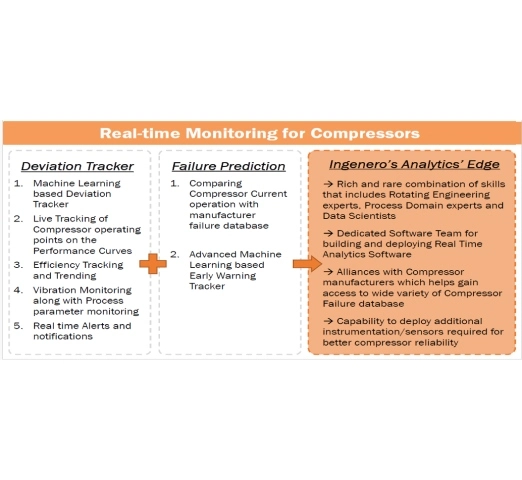

Optimizing Compressor Operations

Compressors are vital components in industries ranging from oil and gas to manufacturing, responsible for maintaining optimal pressure levels in various processes. However, factors like wear and tear, fluctuating demand, and suboptimal operating conditions can compromise their reliability. INGENERO's with its HMC-C solution employs an AI-driven approach and leverages machine learning models trained on historical and real-time data to forecast compressor performance and identify inefficiencies. By monitoring key parameters such as vibration patterns, discharge pressure, and energy consumption, their solutions enable pre-emptive actions to mitigate potential issues, ensuring continuous operation and reducing maintenance costs.

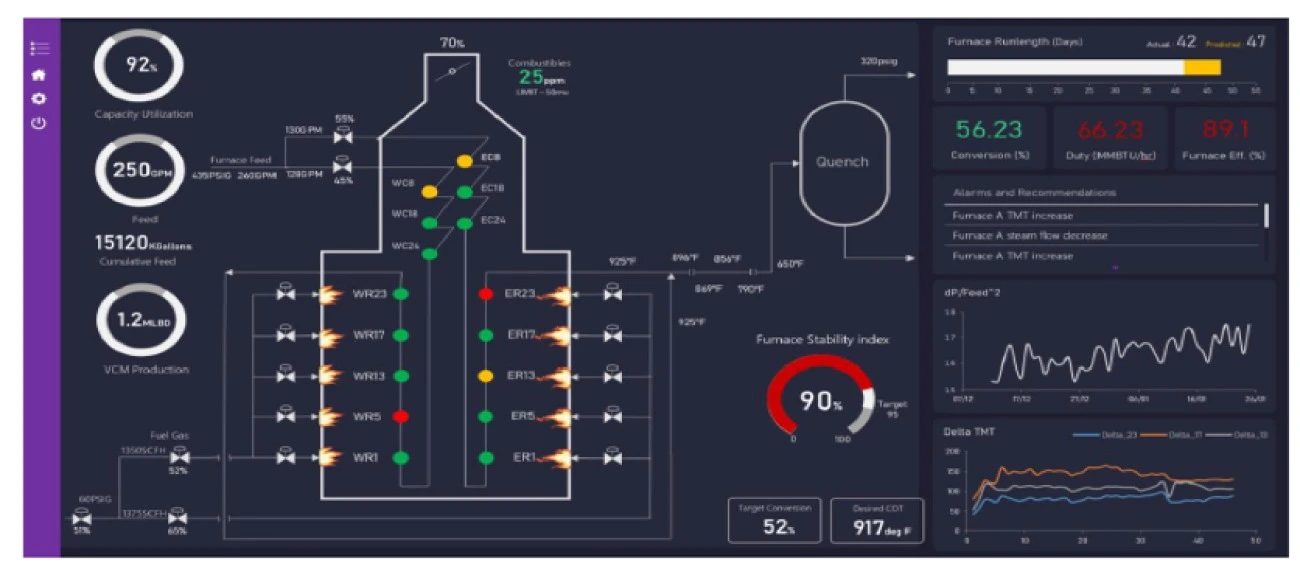

Maximizing Furnace Efficiency

INGENERO’s HMS-F solution employs latest ML/AI analytical techniques for enhancing furnace operations. Operations can monitor and track furnace health in real time and detect health/performance degradation such as coke formation during thermal cracking. HMS-F solution provides insights and intelligence for operators to take action to arrest further deterioration and extend furnace run length.

The solution defines threshold limits for an furnace representing its end of run limit and provides notifications accordingly on time remaining, thereby improving scheduling, maintenance, and operations.

Frequently Asked Questions

APM systems use real-time data and asset performance monitoring to predict equipment failures before they occur. By analyzing historical performance, these APM solutions can forecast maintenance needs, minimizing downtime and optimizing asset lifecycles. Asset performance management software also integrates predictive models for more efficient maintenance strategies.

Industries such as manufacturing, energy, utilities, and transportation benefit from APM solutions. These sectors rely heavily on machinery and infrastructure, making asset performance management critical for reducing downtime and optimizing asset performance. Such enterprise asset performance management also helps maximize asset utilization and minimizes operational costs in these industries.

APM services focus on continuous monitoring and real-time analysis of asset health, leading to more informed decisions. By leveraging asset performance analytics and asset strategy and performance management, companies can improve reliability, predict failures, and extend asset lifespan. This results in better overall performance and reduced maintenance costs.

APM software helps identify inefficiencies and optimize asset utilization. By providing insights through asset performance management software, companies can reduce unnecessary maintenance, improve operational efficiency, and minimize unplanned downtime. This ultimately leads to cost savings by maximizing the lifecycle of assets and reducing the need for expensive repairs.

APM software ensures that assets operate within required safety standards and compliance regulations. Through continuous monitoring, asset performance management systems track regulatory requirements, flagging potential issues before they become violations. This helps companies stay compliant, avoid fines, and maintain operational standards, particularly in regulated industries like energy and utilities.

Leading APM software solutions provide comprehensive asset performance monitoring, predictive maintenance, and data-driven analytics capabilities. These solutions offer integrated tools for these functions, optimizing performance and cost across various industries. While various vendors offer robust platforms, INGENERO delivers tailored strategies designed to maximize asset efficiency and drive sustainable growth.