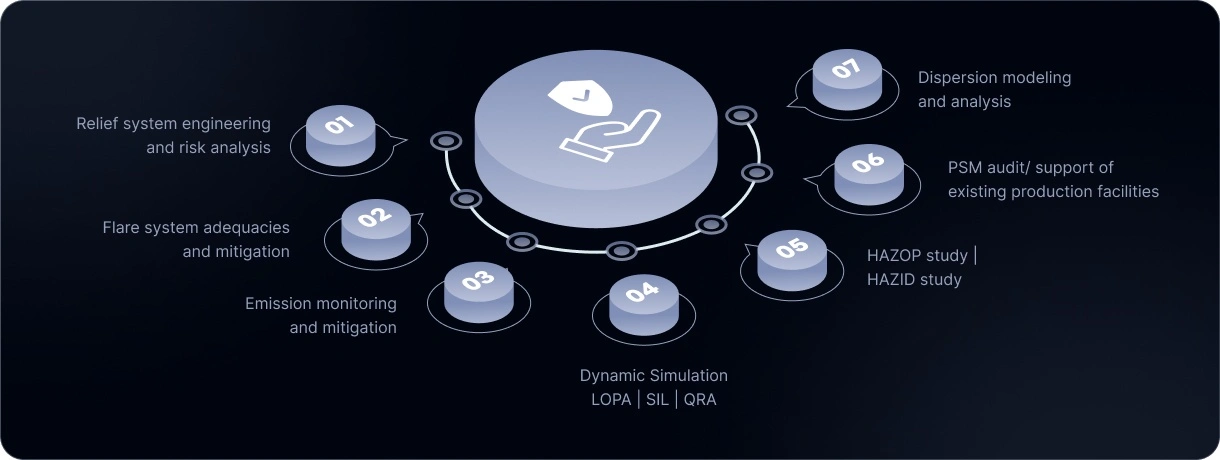

Process Safety Management Services

Optimize Relief System Adequacy with Risk Assessment

Ensure relief system adequacy and optimal design with proactive, responsive approaches. Address potential issues to enhance system reliability.

Ingenero's process safety division specializes in relief device documentation and compliance with regulation and standards. We also have decades of expertise in overpressure analysis, safety consulting and training, and risk management services. With comprehensive expertise In pressure relief devices and systems, we provide a variety of services to support your facility's needs.

Relief System Engineering:

Ingenero's expertise in these critical areas ensures effective risk mitigation, asset protection, and environmental safety in complex industrial operations.

Relief systems often face multiple issues in operations. Some common deficiencies in relief devices include:

- Inlet and outlet piping pressure loss

- Insufficient relief area

- Inappropriate set pressure

- Lack of relief protection

- Relief temperature concerns

Ingenero offers comprehensive relief system engineering solutions.

- Design and analysis of Pressure Safety Valves (PSVs) to prevent overpressure incidents.

- Flare studies for the safe disposal of excess process fluids during emergencies.

- Dispersion analysis to assess the potential impact of hazardous releases.

Safety Studies for Process Safety Management

Ingenero has decades of experience helping you ensure that your operations are the safest that they can be. We have carried out hundreds of studies in the following categories:

Codename SECURUS

Ingenero proudly presents its advanced software tool for safety relief devices.

- Centralised Repository: Accessible globally with strong access control.

- Comprehensive Data Management: Stores extensive device and equipment information.

- Project Preferences: Customisable upfront settings.

- Manufacturer Sizing Coefficients: Simplifies device selection.

- Extensive Chemical Database: Supports various scenarios.

- Custom Component Definition: Accommodates different units of measurement.

Our tool provides robust analysis capabilities,which including:

- Equipment Definition: Specify equipment and relief devices.

- Scenario Flexibility: API or user-defined scenarios.

- Calculations: Relief rates, sizing, hydraulics, AIV screening, and more.

- Report Generation: Includes validation, backup, project documents, and detailed reports.

Learning Opportunities

In addition to our engineering services, we offer a variety of deep-dive learning opportunities, including a two-day [20 hour] Relief System Design course for companies as well as shorter seminars on specialized topics.

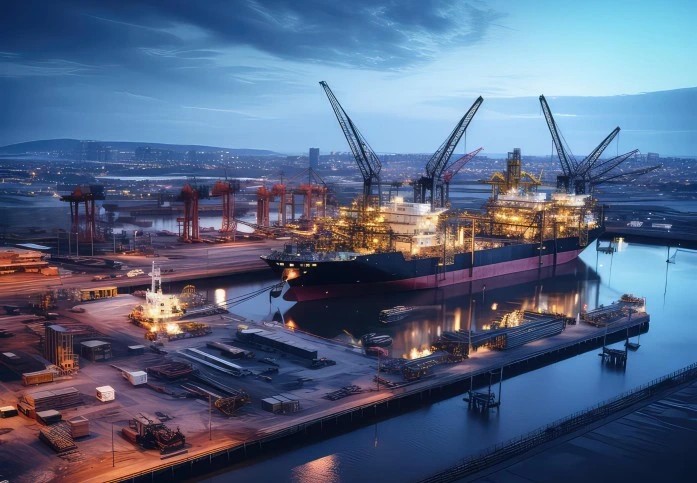

Broad Experience

Having invested more than 3 million man-hrs till date in analyzing processing facilities for overpressure protection across the globe, our experience shows than 25-30% of the relief devices have deficiencies. Uncovering and mitigating these deficiencies is critical to enhancing safety of operations.

Relief devices validated and designed as per API 520/521 standards to comply with OSHA regulations

Refineries, Oil & Gas and Petrochemical facilities analyzed

Engineers with Pressure Relief Device analysis and evaluation experience

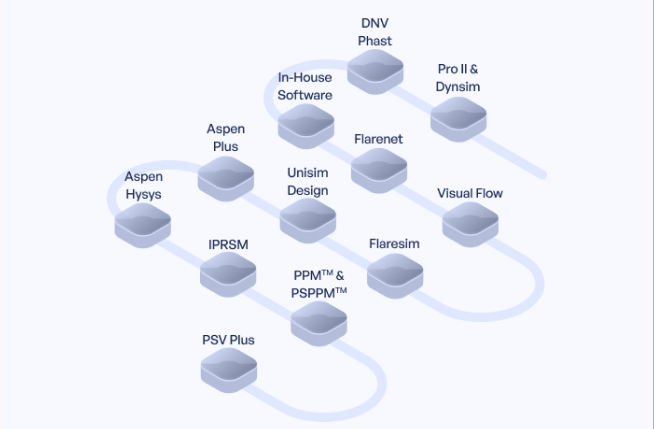

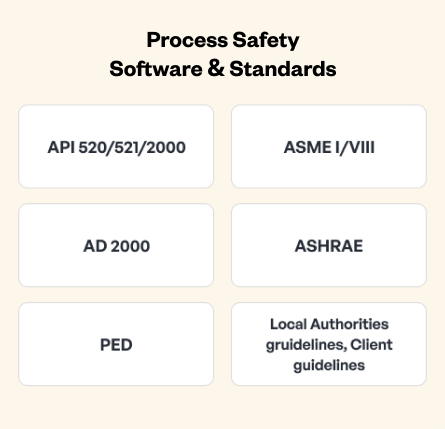

Process Safety Software & Standards

We are experienced in a multitude of software & standards specified by clients and regulatory bodies

Expert Process Safety Management Consulting

We have done Pressure Relief Analysis for a wide variety of processes and unit operations

- Crude Units

- Ethylena

- Vacuum Unit

- EDC/VCM

- Fluidized Catalytic Cracking

- Butadiene

- Cokers

- Clor-Alkeli

- Aromatic Units

- Cumene/Phenol

- Reforming Units

- Polyethylene

- Isomerization

- HDPE, LDPE

- Hydrotreaters

- LPG Terminals

- SRU and TGU

- Tank Farms

- Amine Treatment & SWS

- Boilers

- Ammonia Terminals

- Gas Gathering Stations

- Alkylation

- Lube Oil Additives

- Gas Processing Plants

Frequently Asked Questions

A safety management consultancy helps businesses identify hazards, implement risk controls, and comply with safety regulations. By providing expert advice, customized safety programs, and audits, they enhance safety culture and reduce workplace accidents. Their guidance also ensures businesses maintain a safe working environment for employees.

Process safety consultancy firms provide services like hazard analysis, risk assessments, safety audits, and emergency response planning. They help companies develop and implement effective process safety management consulting strategies, ensuring compliance and mitigating risks associated with industrial operations. These services are necessary for maintaining safe and efficient processes.

Process safety consulting is vital for industries to prevent accidents, protect workers, and comply with regulations. Process safety consultants help businesses mitigate risks, improve operational efficiency, and avoid costly disruptions by identifying potential hazards and recommending preventive measures. It ensures long-term safety and operational continuity.

A process safety consultant identifies potential hazards, assesses risks, and designs safety strategies to reduce accidents. By conducting dust hazard analysis, hazard identification studies, and safety audits, they guide industries in implementing proper controls. Their expertise in process safety management consulting ensures the prevention of costly industrial accidents.

Industries such as manufacturing, pharmaceuticals, agriculture, and food processing often require dust hazard analysis consultant services. These industries involve materials prone to dust explosions, and a dust hazard analysis consultant near me can assess risks, implement controls, and ensure safety compliance to prevent accidents caused by combustible dust.

Safety management system consultants help businesses establish effective safety systems, ensuring compliance with regulatory standards and improving workplace safety. They assist in designing and implementing tailored safety programs, conducting audits, and offering training to employees, ensuring a safer working atmosphere and reducing the risk of accidents.

By implementing process safety management consulting practices, businesses can identify potential hazards, develop safety procedures, and ensure equipment reliability. A process safety consultant helps create systems to control risks, such as emergency shutdowns, maintenance schedules, and employee training, reducing the likelihood of workplace accidents and ensuring compliance.