Your partner in process analytics and technical consulting

We deliver innovative engineering solutions and digital transformation services for clients in the energy and chemical industries.

Ingenero by the Numbers

20M+

Data Points Analysed Daily

16M+

Process Engineering Manhours

1.6K+

Process Studies conducted

100K+

Relief Devices Handles

500+

Applied AI Solutions Use Cases

Value Capture from Digital Solutions

> 18%

Production> 25%

Emission Reduction> 12%

Energy Savings

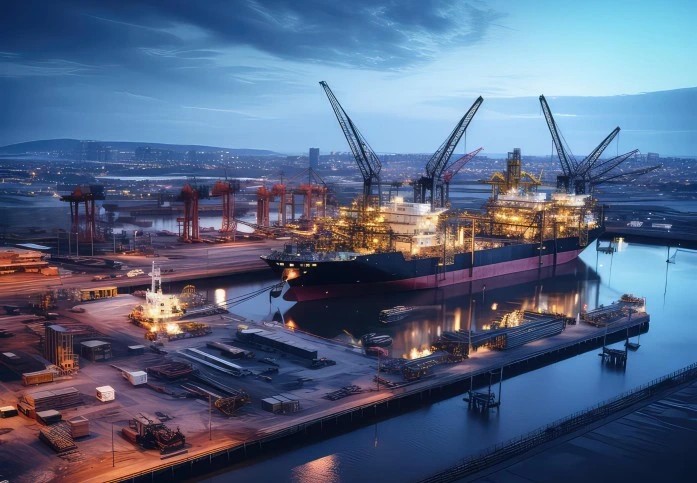

Industries We Serve

Oil And Gas

Petrochemical

Refining

Power And Utilities

FAQS

Process consulting in industrial operations focuses on evaluating, improving, and optimizing processes across various industries. Experts in process improvement consulting and chemical and process engineering analyze workflows to identify inefficiencies, recommend improvements and enhance operational performance, driving cost savings and productivity in manufacturing and petrochemical sectors.

Chemical and process engineering enhances efficiency by optimizing production systems, designing streamlined workflows, and introducing advanced technologies like robotic process automation consulting. This reduces waste, lowers energy consumption, and boosts throughput, improving overall system performance and reducing operational costs.

Chemical and process engineering is used for designing, analyzing, and optimizing industrial processes, such as those in chemical plant design, petroleum refining, and petrochemical engineering. It helps ensure efficient production, resource management, and safety across industries like oil and gas, manufacturing, and pharmaceuticals.

Process improvement consulting services focus on identifying operational inefficiencies and recommending actionable solutions. Through process mapping consulting, process design chemical engineering, and process transformation consulting, experts streamline workflows, reduce delays, and improve resource utilization. This increases overall productivity and operational output.