Over the years, enterprise sustainability has shifted from being merely a cost and compliance-based constraint, to becoming a necessity for future growth, given the depleting non-renewable input resources and the changing market sentiments. Extensive sustainability programs help companies optimize resource consumption. C-level executives across the industry are moving quickly to adopt these practices. Doing so not only drives environmental competences and brand value, but also reduces risk by exploiting growth through innovative products and services. Sustainability can now be a key differentiator and a strategic business imperative that can help drive performance and accelerate top-line growth.

The importance of sustainability

The oil and gas industry has found itself at a crossroads since the turn of the decade. While the demand for oil and gas has stayed relatively high for the past couple of years, the fact remains that these are non-renewable resources. Faced with such certainties, the industry has looked to turn the corner over the last decade by utilizing technology for two distinct purposes:

- Building a sustainable business operations model

– Using renewable resources

– Recycling

– Reduction in inputs consumption per unit of product - Developing a Health, Safety, and Environment (HSE) strategy

Sustainability has considerable significance on social, economic and environmental metrics. Enterprises that incorporate sustainability into their underlying philosophy and everyday operations stay profitable in the long run. Although sustainability is often considered to be analogous to investment in renewable energy in the energy industry, it also impacts business operations. As such, businesses that embrace a more rounded approach manage to reduce costs while raising their equipment availability, decreasing energy consumption, minimalizing releases and accidents, increasing employee training, and enjoying many other benefits.

How to efficiently achieve it through digitalization

An effective Digital Transformation, utilizes Digital tools to convert data to Augmented Intelligence that enables closer to real time access to decision quality information. This enables optimal specific consumption of inputs and a better HSE profile.

Sustainability and digital transformation need to be more than just industry buzzwords — they need to be effectively implemented with cogent guidelines and seamlessly integrated into business operations.

How can these notions become concrete benefits for an enterprise? And how can we utilize digital transformation tactics?

Matured technologies such as ‘cloud computing’ or ‘edge computing’ can now be integrated with Advanced Analytics, into present operational configurations to accurately grasp the potential of the Industrial Internet of Things (IIoT). The current advancements in smart technologies (sensors, field devices, wireless devices, etc.) and their availability and cost in the current market are making implementation an attractive option for operators in the oil and gas industry. By combining these technologies, IIoT can act as a force multiplier and allow firms to advance their energy management, safety modeling and automation processes. Innovative technology solutions are helping enterprises through improved efficiency. For example, edge computing requires devices and gear to be placed at the edge of an integrated network, thereby lessening latency and improving performance. This technology is considered especially useful in remote areas to monitor pipelines and ensure optimal performance levels. This in turn helps the floor team quickly locate divisions that need upkeep or immediate replacing, thus saving time, energy, and money, as well as avoid potential accidents. IIoT merged with digitalization solutions delivers better visibility across a facility’s energy use, power value and asset well-being in real-time, giving the operators enough time to develop energy proficiency needs. This focus on the use of smarter energy helps operators extend the life of critical equipment while reducing the risk of failure and protecting their workforce. Additionally, digital twin models can be set up to imitate actual physical assets and provide integrated data and information, whether that be for a refinery, petrochemical plant or other domains.

For any enterprise to become sustainable and hit efficiency targets, the installed devices cannot operate in isolation. In fact, these devices must be installed to be interconnected and help relay information between individual units and a central monitoring system. This permits an operator access to dashboards that help gain superior insight into systems and help predict problems before they occur.

Here’s how Ingenero can help!

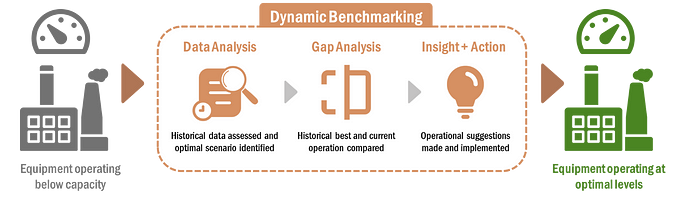

Ingenero offers many products and software solutions across multiple industries. Keeping the words sustainability and digitalization in mind, Ingenero offers two flagship solutions — IPOG and I-SSPDE (you can learn more about them in some of our previous posts). Essentially, these programs help manufacturers improve and sustain their operational performance and support their digital transformation to create significant profit opportunities. With any program or solution, KPIs must be tracked to provide both an intrinsic and extrinsic view of the process/equipment. Ingenero’s dashboard encapsulates the three industry standard dashboards into one. it provides:

- An Operational Outlook — interprets large amounts of information, provides continuous real time data to operators in a single, clear visual.

- An Analytical Outlook — allows for further investigation into the data received through KPIs, enables users to investigate any anomalies in the data and uncover its root cause.

- A Strategic Outlook –allows users to receive simulated solutions for any problems that the system identifies, thus highlighting any opportunity to optimize.

Conclusion

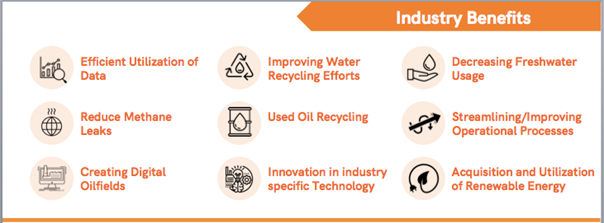

Gradually, we’re seeing a lot more firms in the oil and gas and petrochemicals industry appreciating success by utilizing a wide range of technologies and solutions that support their new company philosophy to minimize costs, be more sustainable and reduce their carbon footprint.

Here are some of the key areas to benefit:

In conclusion, sustainability and profitability cannot be considered as mutually exclusive theories. The industry is gradually understanding that this does not always translate to smaller profit margins. The industry might even have to go through increasingly regulated and strict frameworks in the coming years for the public good. But fortunately, by initiating the process to construct an integrated and digitized infrastructure, enterprises can rise up to the expectations of achieving environmental and operational sustainability while remaining profitable. By introducing sustainable policies and processes with the help of digitalization strategies, greater proficiencies can be seized, and operators along with their companies can position themselves to experience smarter long-term benefits.

For more information around our digitalization offerings, reach out to us at usa@ingenero.com or visit our website www.Ingenero.com.