Rising fuel costs, emission regulations, and equipment efficiency demands are pushing industries to rethink how they manage engine health. In fleet and industrial settings, even minor performance losses due to carbon buildup can result in higher fuel consumption, unplanned downtime, and long-term wear. That’s where engine decarbonization comes in.

By removing harmful carbon deposits, it restores engine efficiency, reduces emissions, and extends the life of critical assets. When offered as a service, it becomes a practical, scalable solution for companies seeking cost-effective ways to enhance performance while supporting sustainability goals.

What is Engine Decarbonization?

Engine decarbonization refers to the process of removing carbon deposits that accumulate inside internal combustion engines over time. These carbon buildups, caused by incomplete fuel combustion, often form on intake valves, pistons, injectors, and other key components. Left untreated, this carbon buildup can lead to reduced fuel efficiency, engine knocking, increased emissions, and long-term performance issues.

The decarbonization process can be mechanical, chemical, or even automated-depending on the level of buildup and the engine type. As fleet and industrial vehicle operators face mounting pressure to improve efficiency and reduce emissions, engine decarbonizing has become a critical part of maintenance strategies.

How “Decarbonization as a Service” Works

“Decarbonization as a Service” is a growing model where specialized providers offer engine decarbonization as a scheduled or on-demand solution. Instead of relying solely on in-house teams or traditional servicing intervals, businesses can now access expert-level decarbonization services through external partners.

Here’s how it typically works:

- Assessment: Service providers begin with a diagnostic scan or physical inspection to assess the extent of carbon buildup.

- Customization: Based on engine type (diesel, petrol, CNG, industrial), they select the appropriate decarbonization technology and method.

- Execution: The service is performed using chemical or hydrogen-based cleaning agents, ultrasonic cleaning, or manual techniques.

- Validation: Post-cleaning, a performance test ensures restored efficiency and emission compliance.

This service model offers predictable maintenance scheduling, minimal downtime, and access to the latest decarbonization technology without the need for in-house investment.

Key Benefits of Engine Decarbonization for Fleets and Industries

For fleet operators and industries that rely on high-utilization engines, the value of a reliable engine decarbonization service cannot be overstated. It directly results in:

- Improved Fuel Efficiency: Clean combustion chambers allow fuel to burn more completely, increasing mileage per liter.

- Extended Engine Life: Regular decarbonizing reduces wear and tear on engine components, delaying major overhauls.

- Lower Emissions: By improving combustion, decarbonization technology reduces harmful CO2, NOx, and particulate emissions.

- Restored Performance: Engines regain lost horsepower, responsiveness, and smooth idling after carbon removal.

- Reduced Maintenance Costs: Early carbon removal prevents issues like misfiring, clogging, or overheating that could lead to more expensive repairs.

In industrial environments, where engine efficiency is directly tied to production uptime, these benefits make decarbonization as a service a high-ROI investment.

Environmental Impact of Engine Decarbonization

Engine decarbonizing plays a significant role in the broader decarbonization process, contributing to cleaner air and reduced greenhouse gas emissions. By enabling engines to burn fuel more efficiently, fewer pollutants are released into the environment.

In sectors where electrification is not immediately viable, such as heavy-duty transportation, mining, or marine operations, engine decarbonization service serves as a practical bridge to longer-term sustainability goals.

Key environmental benefits include:

- Lower Carbon Footprint per Vehicle: Improved combustion leads to measurable reductions in CO2 emissions.

- Compliance with Emission Standards: Regular engine cleaning helps fleets meet tightening emission norms.

- Support for ESG Goals: Companies can incorporate decarbonizing services into their sustainability reporting as part of emissions mitigation efforts.

As regulatory frameworks continue to tighten, decarbonization technology will play an increasingly strategic role in meeting emission reduction targets. Want to advance your business’s environmental objectives and ensure compliance? Discover how.

Industries and Applications of Decarbonization Services

Engine decarbonization as a service is gaining traction across multiple industries that rely on combustion engines for critical operations:

- Logistics & Transport Fleets: Delivery vans, trucks, and last-mile vehicles benefit from fuel savings and extended uptime.

- Public Transport: Buses operating in dense urban areas are often targeted for frequent engine decarbonizing to reduce local emissions.

- Construction & Heavy Equipment: Earthmovers, cranes, and generators see extended engine life and reduced black smoke.

- Oil & Gas: Industrial generators and pumps used in upstream or downstream operations are decarbonized to improve operational reliability.

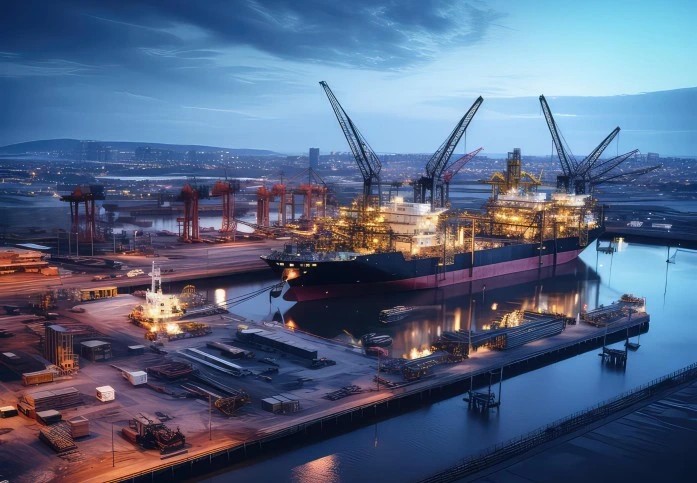

- Maritime: Fishing and cargo vessels apply decarbonization technology to enhance engine performance during long voyages.

- Manufacturing Plants: Facilities using backup or peak-load generators benefit from cleaner, more efficient engine cycles.

In each of these applications, decarbonization service providers offer industry-specific packages tailored to engine types, usage cycles, and emission requirements.

Challenges in Engine Decarbonization

Despite its clear advantages, engine decarbonization also faces operational and adoption-related challenges:

- Lack of Awareness: Many fleet operators remain unaware of how significantly carbon buildup impacts performance and emissions.

- Service Quality Variance: Without standardized practices, the quality of decarbonization service can vary widely across providers.

- Downtime Concerns: Even with mobile servicing, temporary equipment downtime can be a concern for high-throughput operations.

- Cost Sensitivity: For businesses operating on thin margins, the upfront cost of regular decarbonizing may be seen as non-essential, despite long-term savings.

- Technological Barriers: Selecting the right decarbonization technology depends on factors such as engine design, fuel type, and compliance goals, making expertise critical.

As the market matures, addressing these challenges will be key to broader adoption, particularly through education, standardization, and bundled fleet service offerings.

Conclusion

Decarbonization as a service is more than a maintenance trend, it’s becoming a core strategy for improving engine health, meeting emissions standards, and reducing operational costs in fleet and industrial environments. As fuel efficiency and sustainability take center stage, more organizations are turning to specialized engine decarbonization services to keep their equipment running cleaner, longer, and smarter.

With the right partners like Ingenero, businesses can integrate decarbonization into their regular maintenance schedules and benefits across performance, compliance, and environmental impact. With deep expertise in asset optimization and engineering services, Ingenero helps organizations implement decarbonization strategies that are not only effective but tailored to industry-specific operational requirements. Whether you’re running critical field machinery or managing high-volume transportation fleets, Ingenero’s solutions are designed to reduce emissions, enhance fuel efficiency, and extend asset life without disrupting uptime.

FAQs

Engines used in power generation, combined heat and power systems, and various industrial processes can benefit from decarbonization by improving efficiency and reducing emissions, aiding in achieving sustainability goals.

Yes, decarbonization services assist energy companies in reducing greenhouse gas emissions, enhancing energy efficiency, and transitioning to low-carbon technologies, thereby facilitating compliance with environmental regulations and supporting climate objectives.