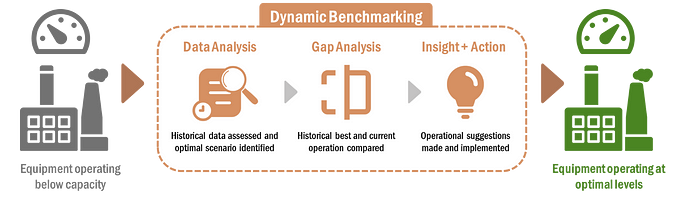

Downstream oil and gas manufacturing plants use complex equipment that are set up to optimize KPIs like capacity utilization, yield optimization, energy optimization and quality management. Over the years, operations have stayed on target and realized goals through process control systems with Unit Optimization, advance planning, and scheduling. As the industry evolves, smart manufacturing technologies are becoming more of a necessity than ever before. Keeping pace with industry 4.0 transformation, Ingenero has developed the robust, self-sufficient Dynamic Benchmarking Tool, which identifies areas of improvement and provides continuous attention for manufacturing units on a real-time basis.

Dynamic Benchmarking — a real-time solution powered by analytics

Dynamic Benchmarking is a digital solution hosted on a scalable software platform which identifies periods of historically optimal operation for a given equipment based on certain predefined operational KPIs. It simultaneously ensures that this historical best operation closely matches but shows room to improve over the current operation of the equipment.

The tool covers scope of improvisation for operation of various critical equipment in downstream oil and gas, such as furnaces, compressors, splitters, fractionators, chilling trains, refrigeration compressors, and more.

Historical best operation is identified by looking at the past 3 years (variable) of historical data. It is also ensured that the historical best operation satisfies the user defined external target(s) in DMC. This drives the performance of the equipment and subsequently, the entire unit in the desired direction, while providing guidance to achieve the best possible operation.

Working Philosophy- Minimizing Operational Gaps using insight from tags

The software solution uses different processes across all equipment, which are distributed among different categories within the Dynamic Benchmarking tool: external targets, performance tags, match tags and result tags. For a given equipment, all required historical data points have corresponding current values of Match Tags (within the defined relaxation/tolerance band), which are subsequently identified. This identified set of historical data points, which matches with the current operation, are then compared with the current operation so as to satisfy the specified performance condition (either maximum or minimum) as specified using the performance tag.

While finding the historical best values, user specified ranges of the external targets are taken into account so as to ensure that the identified historical best operation lies within the minimum and maximum bounds of the active external target(s) specified by the user.

Match tags are essentially used to form a model envelope between current and identified historical best case to help bringing a closer comparison between two operations while DMC variables with user defined set limits also take part in Match Criteria calculation as External Target Tags. The search will be refreshed automatically in every 10 minutes interval and results will update with changing match conditions as per real time plant operation.

How Ingenero Can Help

In view of the industrial leap towards Industry 4.0 automation and sustainability, Ingenero offers products and software solutions across industries. These help manufacturers improve and sustain their operational performance and support their digital transformation. One of these flagship solutions is I-SSPDE (or Intelligent Software Solution for Process Decision Excellence). With dynamic benchmarking tool being an indispensable part of I-SSPDE solution, important plant KPIs and external targets are being tracked and optimized to create significant profit opportunities.

Ingenero’s Dynamic Benchmarking Tool ensures optimal operations by focusing on:

- Limits, color coding and appropriate threshold for output tags that helps generating timely yet important alerts eliminating unnecessary alerts and distractions.

- Precise selections of performance tags based on process improvement opportunities as well as equipment degradation scenario, deviation of which helps operator to draw proper and timely inference and thereof guiding the unit towards best operation scenario.

- Specified range of External Targets with flexibility of change/ modification, helps equipment as well as entire unit adhering standard operating conditions and best operation practices.

- Link to historian for auto analysis and live tracking through built in trending feature that helps identifying point of deviation even in a consistent operation.

Dynamic Benchmarking Applications

1) Improving overall furnace capacity and effectiveness by finding opportunities, addressing constraints, and maximizing optimization

- Maximize Capacity

- Improve Yields: Identifies the max. achievable ethylene yield for user specified conversion, feed, SHC etc. while considering the furnace run length and process opportunities to improve.

- Reduce SCR Temperature

- Minimize Stack Temperature

- Minimize Convection bank Temperatures.

- Optimize Energy and Minimize BTU requirement.

2) Optimize process to improve heat recovery, heat and mass transfer rates, and reduce steam requirement, fouling & compressor load:

- Maximize heat recovery in quench oil circuit.

- Adjust circulation rates to improve mass/heat transfer.

- Reduce Quench temperature and pressure.

- DSG optimization — header pressure, heat recovery.

- Reducing steam requirement.

3) Identify opportunities to improve compressor and turbine operation, processing capacity, and suction pressure reduction, leading to improved yields, recovery and plant capacity in constrained scenarios:

- Charge Gas Compressor: Improve operation to reduce suction pressure, identifying opportunities to improve RPM and capacity.

- Caustic Tower: Tracking fouling and optimizing PDI, prevent Amine/CO2 carryover, reducing utility cost etc.

- Condensate Stripper: Maintain and control ethylene slippage.

- Propylene and Ethylene Refrigeration Compressors: Improve recovery or capacity by minimizing suction pressure.

4) Real time analytics maximize column performance, processing capacity, product quality, recovery, and energy efficiency.

- Optimize hydraulics to improve capacity.

- Track and reduce column pressure differential.

- Energy efficiency improvement.

- Product quality control.

- Product recovery maximization.

- Minimizing the plant recycles and vent flow.