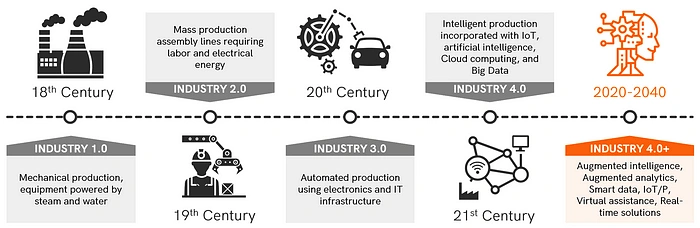

The world has gone through three industrial revolutions over the past three centuries Now, a fourth revolution is being powered by digital technology innovations including Big Data Analytics, the Industrial Internet of Things, Cloud & Edge computing and Artificial Intelligence. This revolution, known as Industry 4.0, merges physical and virtual aspects of manufacturing. Industrial digital transformation creates significant profit opportunities for manufacturers.

The application of Industry 4.0 technologies drives increased global collaboration within businesses. Companies can analyze & process massive amounts of existing and new data in a continuous learning mode. This, in turn, offers real time insights (Augmented Intelligence) to every aspect of operations creating new levels of operational excellence and efficiencies across manufacturing and supply chain logistics.

To initiate/approach Digital Transformation, every firm needs to clear two essential steps:

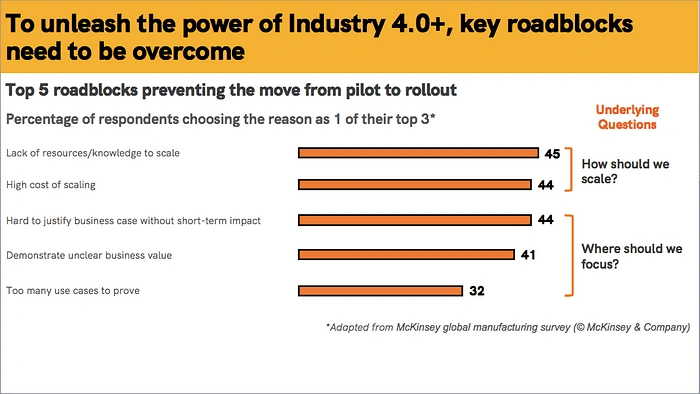

STEP 1: Identify obstacles to success

As with past industrial revolutions, companies able to embrace and adopt new approaches survive and thrive. The rapid change over the last 30 years of the top companies in the S&P 500 illustrates this clearly. Companies must adapt to new paradigms at an increasing rate. Over 90% of decision makers believe that they will be left behind by their competition, if they don’t digitalize.

Successful digital transformation strategy and execution begins with these objectives/goals in mind:

- Exponential gains in productivity

- Safety

- Reliability

STEP 2: Utilize key factors and set organizational objectives

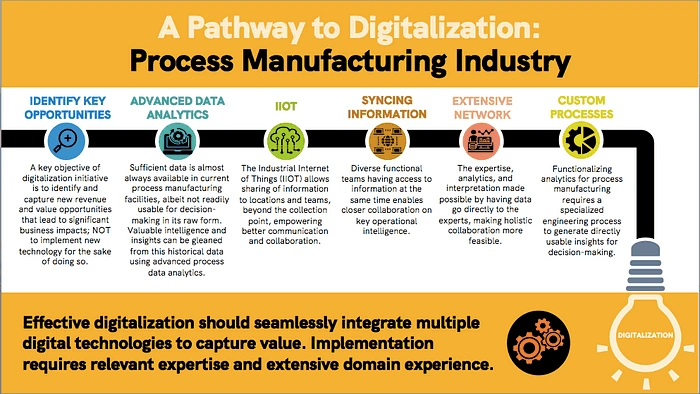

Digitalization, if implemented properly, achieves better, sustainable plant performance by assisting decision makers. It provides relevant information at the right times by augmenting human intelligence with timely operational insights. Here are some of the key factors that help provide these insights and enable sustained operational excellence:

- Analytics of vast historical data

- Leveraging technologies like digital twinning (digitally replicating a real plant’s setup and behaviors)

- Utilizing The industrial Internet of Things (IIOT)

- Artificial Intelligence

- Machine Learning

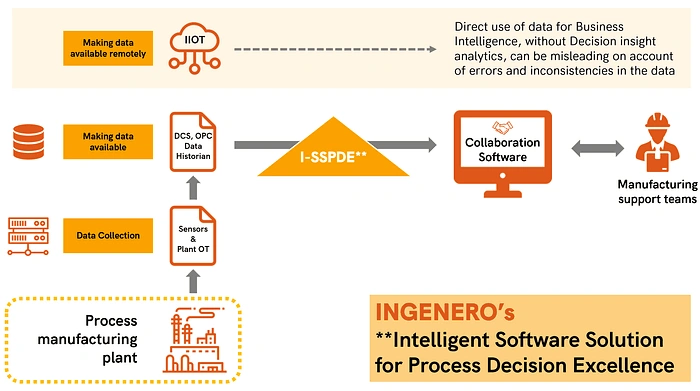

The image below provides a more detailed outlook of the key factors required to reach Digitalization:

Here’s how INGENERO can add value!

INGENERO imbibes these principles represented above, in its Intelligent Software Solution for Process Decision Excellence (I-SSPDE) and empowers digitalization in a robust manner.

Ingenero’s I-SSPDE produces decision insights needed to exponentially increase value capture. By enabling and optimizing data analytics, machine learning and process manufacturing simulation, Ingenero provides companies with the digitalization insights. This digitalization leads to increased throughput, yield & achieving their digitalization goals as it helps stay at the forefront of the Augmented Intelligence Industry 4.0+ Age.

Ingenero’s I-SSPDE processes and analyzes larger and more varied amounts of data, which are collected with higher frequencies. This creates a better representation of reality and enables faster access to near real-time information. It also processes streaming data from operations to automatically provide insights on KPIs such as operational efficiency, reliability, and equipment performance. Continuous comparison with historical benchmarks fosters constant improvement. The analysis and information presentation is securely available regardless of location and enables global collaboration. The latency or distance an operational change and its awareness are no longer constraints to collaboration, enabling a robust decision making process that creates new levels of operational excellence.

For more information around I-SSPDE, reach out to us at usa@ingenero.com or visit our website www.Ingenero.com.

Suggested Read: What Is Edge AI

Sources Consulted

1. “Digital Industrial Transformation”. Deloitte Insights, 2019, https://www2.deloitte.com/us/en/insights/focus/industry-4-0/digital-industrial-transformation-industrial-internet-of-things.html#. Accessed 17 June 2020.

2. Industry 4.0 Capturing Value At Scale In Discrete Manufacturing. McKinsey & Company, 2019, https://www.mckinsey.com/~/media/mckinsey/industries/advanced%20electronics/our%20insights/capturing%20value%20at%20scale%20in%20discrete%20manufacturing%20with%20industry%204%200/industry-4-0-capturing-value-at-scale-in-discrete-manufacturing-vf.ashx. Accessed 17 June 2020.

3. Industry 4.0 Challenges And Solutions For The Digital Transformation And Use Of Exponential Technologies. Deloitte, 2015, https://www2.deloitte.com/content/dam/Deloitte/ch/Documents/manufacturing/ch-en-manufacturing-industry-4-0-24102014.pdf. Accessed 17 June 2020.

4. Industry 4.0: Building The Digital Enterprise. Pwc, 2016, https://www.pwc.com/id/en/CIPS/assets/industry-4.0-building-your-digital-enterprise.pdf. Accessed 17 June 2020.